OSB Long log flaker - Type PZU

We have developed the world’s largest

strander: Due to the design of its knife ring with a 2,500 mm diameter, a

cutting width of 850 mm, 56 knives, as well as a maximum material throughput of

45 metric tons per hour bone dry, the new OSB flaker is considered a giant. Stranders

of the PZU series are able to process logs to high-quality strands with a

specific length, width, and thickness. Therefore, these machines are the best

choice for the production of high-quality flakes in large quantities for OSB

and wafer boards.

Features, Function

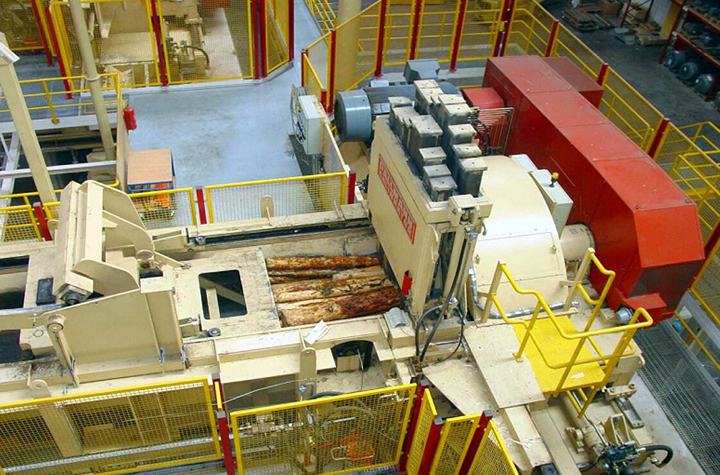

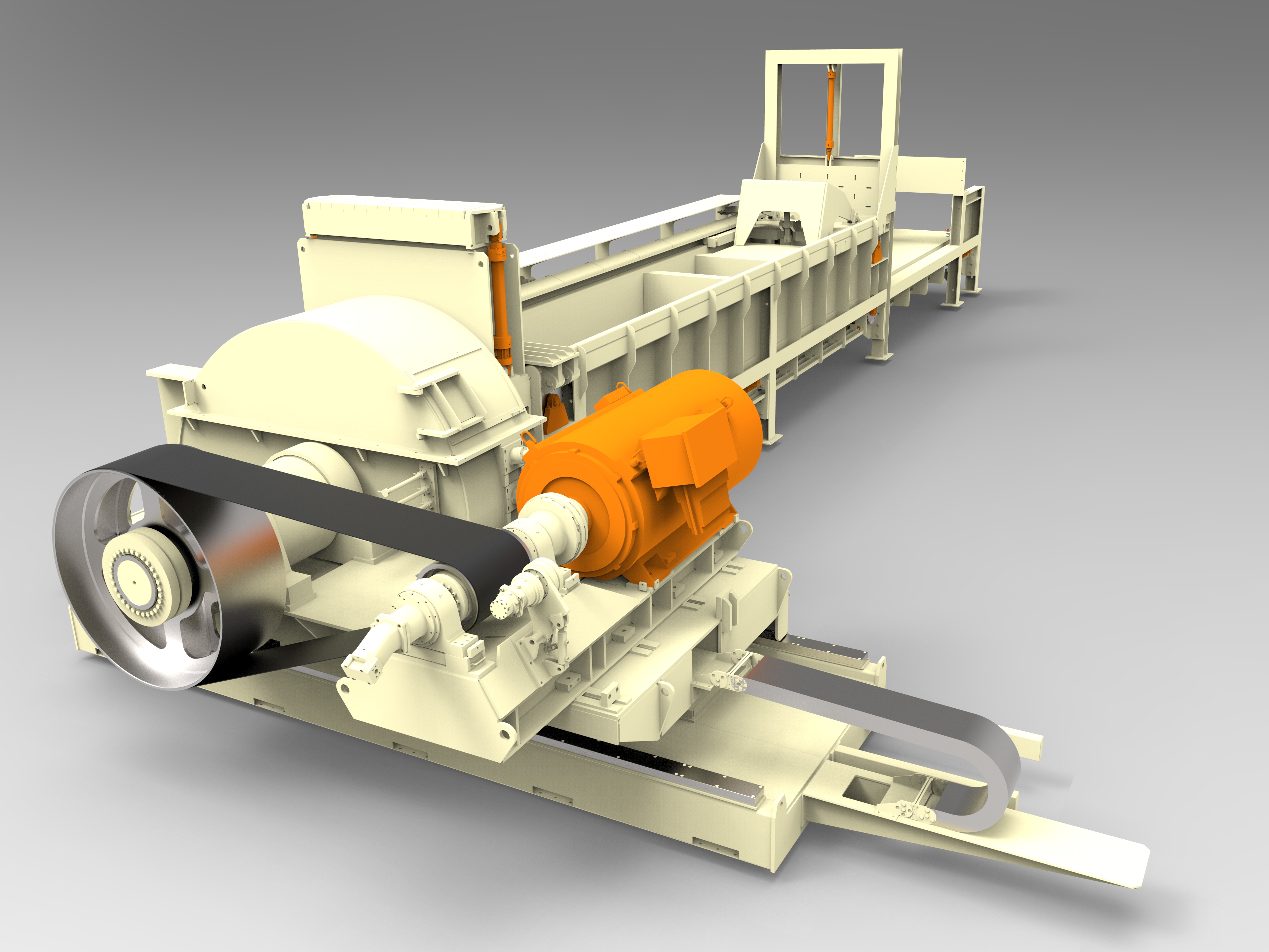

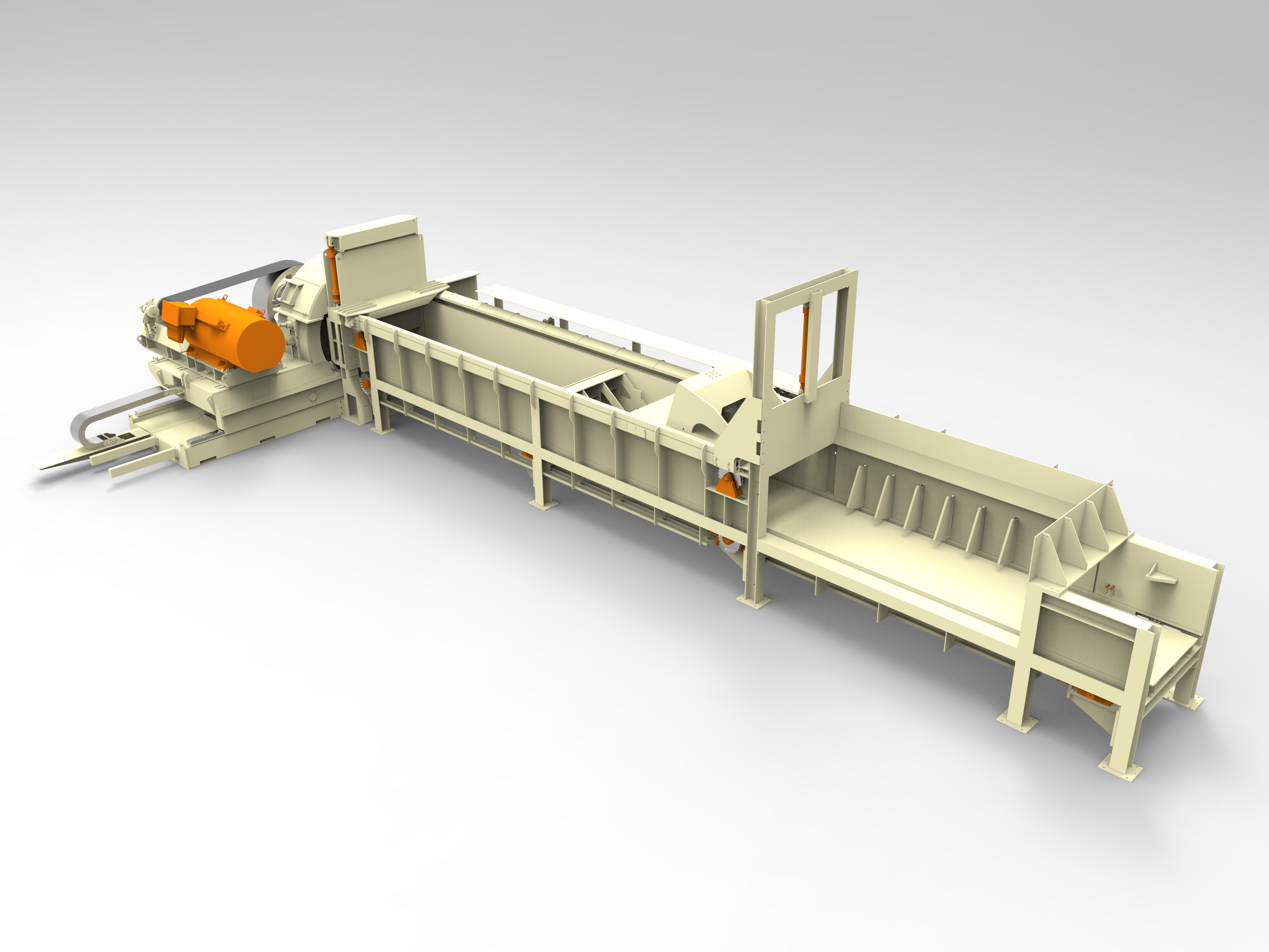

These machines have a modular design and

consist of a loading station and a cutting machine. Logs, the preferred feeding

material, are fed either via a crane from above directly to the loading station

or from a storage deck from the side. The plate conveyor installed directly in

front of the flaker pushes the logs in cycles into the cutting chamber.

To implement even higher throughput amounts

with even higher strand quality, it is recommended to use logs with a length

that is uniform and adjusted to the loading station. The cut-to-length logs are

collected in the feed area via a crane, adjacent supply conveyor, or via a fully

automatic dosing conveyor and then placed in the loading station. After loading

is completed, a log pusher pushes the logs into the feeding area. Another advance

carriage then feeds the batch of logs in cycles to the flaking chamber.

The flaking process takes place in cycles by a

knife ring on the inside of the cutting chamber. The combination of the

high-performance hydraulic positioning unit and the intelligent PLC control

provides for consistent traversing speeds even at varying loads. The knife ring

is made with high accuracy from high-strength, low-wear steels. Since all wear

parts can be easily replaced, high service life of the knife ring is ensured. The

arrangement of the knives in a ring and their angle during cutting allows the

production of flat uniform strands with a smooth surface.

The outstanding function of

the loading conveyors in connection with the perfectly adjusted cutting

geometry of the flaker, allows cutting of the wood parallel to the fiber

direction. Strands with a length of 12 mm to 800 mm and a thickness ranging

from 0.4 mm to 2.0 mm can be produced. The length of the strand is determined

by the scoring tips integrated into

the knife holders . The flaker knives are simple strip knives.

The machine features an almost fully automatic

knife change. During this process several knife assemblies are automatically

released and ejected to the front. Once the new knife assemblies are inserted,

the machine secures the knives in their places, turns the ring, and releases

the next knife assembly for replacement – all fully automatic. In this way,

extremely short knife changing times can be achieved.

Advantages

- Very good ratio between loading and cutting times

- Improved, simpler maintenance

- High strand throughput

- High strand quality with low fines content

- Low energy consumption

Contact Person

Our quality promise