Special Hammer mill - Type PHMC

Surging demand by the pelletizing industry has caused a shortage of available saw dust and shavings. Numerous industries, like wood–based panelboard producers and the power plants are forced to find alternative sources. Substitution of suitable replacements has become urgent to ensure a fibre supply and to prevent shortages. Wood chips are often the only available source.

Because of increasing numbers of produc-tion lines for pellets and particleboard a shortage of small fibre, has resulted. The flake produced from wet wood chips by the optimally PHMC hammer mill, can be used as an additional source or a 100% substitute of saw dust.

Characteristics, Function

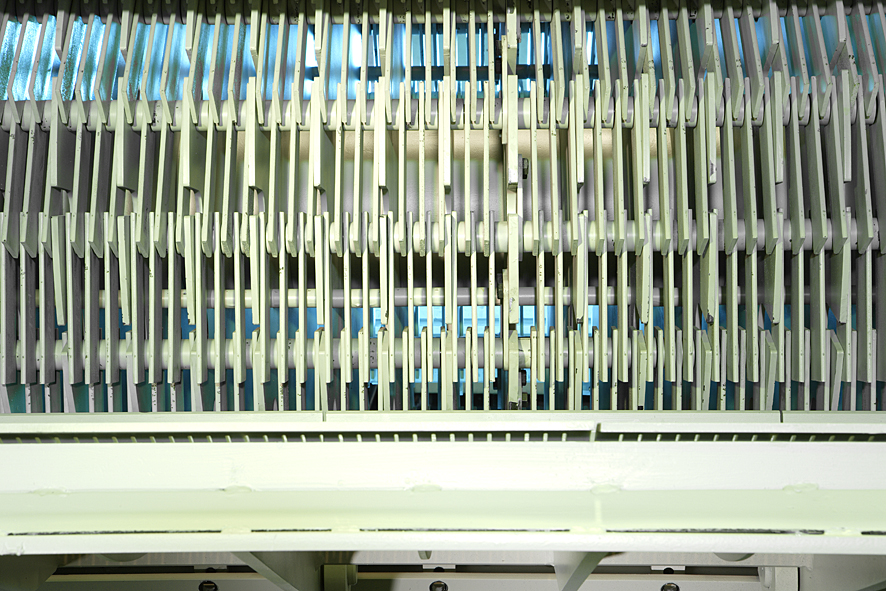

The symmetrically designed machine housing allows operation of the mill in both directions ensuring maximum utilization of the wear and spare parts. The feed material is introduced vertically from above. Flat steel beaters rotating at high speed split the material mostly parallel to the grain. The screen opening determines the size of the finished product. The rotating flat steel beaters can swing back into the refining chamber in case of contaminants or coarse pieces.Multi-stationary refining elements integrated into the mill assist in size reduction.

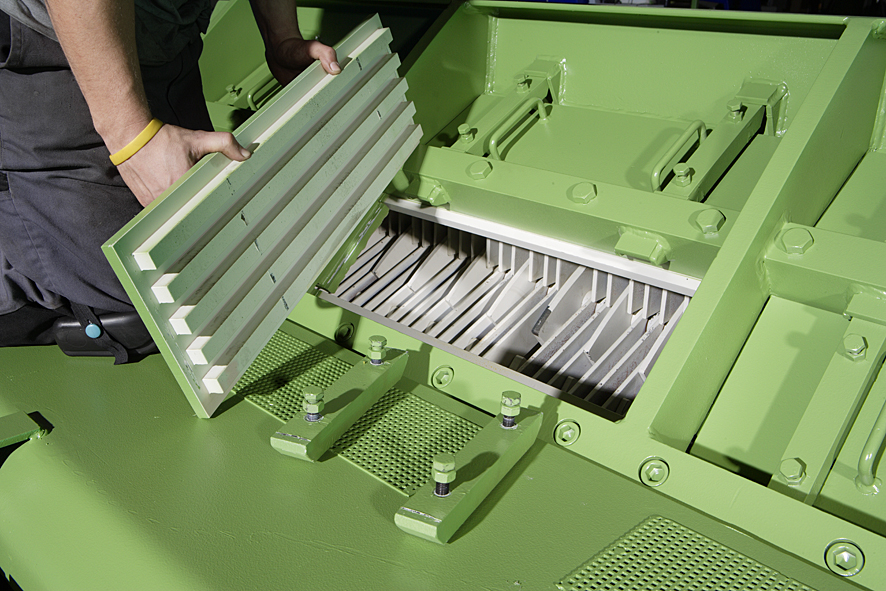

Multi-screen zones allow the usage of variable screen openings in turning direction. Hydraulically driven screen frames allow quick and secure screen change. Cleaning rollers are installed in the housing to keep the housing free of blockage and ensure secure operation especially when extremely wet chips are fed into the machine. The material discharge is to the bottom of the machine, product removal by means of mechanical conveyors, with additional auxiliary aspiration.

Advantages

- Processing of wet chips (moisture u > 100%)

- Flake preparation of chips to a coarse saw dust type material

- Ensure the fibre supply in existing processing lines

- High machine availability at lowest maintenance an labour costs

- Independence from saw dust supply

- Future-proof for the usage of different material types by simple adjustment of the machine settings

Contact Person

Our quality promise